Research

Our research interests fall in the following categories (1) Bioinspired design for multifunctional properties – aeroacoustics, aerodynamics, electromagnetics, among others, (2) Self-aware additive manufacturing for extreme environments, (3) Damage tolerant architected materials for lightweight aerostructures, (4) Multi-physics modeling for investigating structure-property-relationships, and (5) Soft robotics devices for adaptive manipulation. Opening the design space of functional devices that can be printed will drive and revolutionize the face of additive manufacturing. More information is given below by category. Please see our publications page for examples from across these exciting research avenues.

We design bioinspired materials and structures that endow devices and systems with multifunctional capabilities – from tunable electromagnetic response to quiet, efficient flight. In nature, organisms routinely solve coupled challenges in acoustics, sensing, and efficiency using finely tuned architectures rather than added complexity. We translate these strategies into engineered metamaterials and surface topographies that have multifunctional capabilities. On the electromagnetic side, we develop mechanically reconfigurable metamaterials whose spectral properties can be actively tuned for communication, sensing, and shielding. Inspired by the chameleon’s color-changing skin, we created a truss-based microwave absorber that switches between absorbing, transmitting, and reflecting by changing its internal geometry. Coupled with machine learning and genetic algorithms, this platform enables aircraft skins and panels that provide strong electromagnetic interference (EMI) shielding in normal operation while selectively “opening windows” for communication when needed. For aeroacoustics and hydrodynamics, we draw inspiration from owls, cicadas, and mako sharks, whose surface microstructures orchestrate flow control and noise suppression. Using CFD-informed design and 3D printing, we developed drone propellers that emulate owl-feather serrations and cicada-wing geometries, achieving up to 5.5 dB noise reduction and >20% gains in propulsive efficiency relative to industry benchmarks such as the DJI Phantom 3. Other biological systems that we explore include sea sponge for buckling performance, shark skin for drag-reducing underwater vehicles, and fish scales for puncture resistance. Together, these efforts point toward future vehicles that are inherently resilient, adaptive, quiet, and efficient by design.

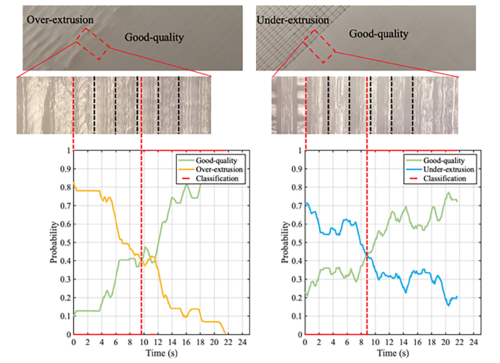

Our research establishes the foundation for autonomous additive manufacturing by integrating machine learning (ML) with real-time process monitoring and control. We have developed frameworks in which ML models, trained on experimental datasets, capture the complex relationships among process parameters, material microstructure, and anomaly evolution. A key contribution is our convolutional neural network (CNN)-based system capable of optimizing process parameters in real time. This system fuses feedback from in-situ sensors to monitor deposition dynamics and detect microstructural anomalies. Through this approach, we demonstrated autonomous correction of under- and over-extrusion events, achieving real-time response faster than human operators. The framework has since been generalized to other defect types, including warping and delamination, and extended beyond fused filament fabrication to direct ink writing. To enhance detection precision, we incorporated computer-vision inspired by object detection in autonomous vehicles, enabling not only defect identification but also localization and segmentation within the build volume. Beyond process control, our work recognizes that environmental factors – temperature fluctuations, vibration, humidity, and gravity – play a critical role in determining print quality. We term this as environment-process-structure-property (EPSP) relationships. Conventional AM systems often lack coordinated sensing and adaptive response to such variations. By integrating AI with multi-sensor data fusion, we can model and compensate for environment-process interactions, enabling adaptive control that maintains print fidelity under variable or extreme conditions. Reinforcement learning and AI-driven digital twins allow predictive control by linking environmental states to structural evolution, anticipating anomalies before they occur. Adaptive additive manufacturing offers the capability for on-demand, autonomous fabrication of mission-critical components in remote or extreme settings, such as in-flight repair, on-orbit manufacturing, or rapid response production in defense and disaster-relief operations.

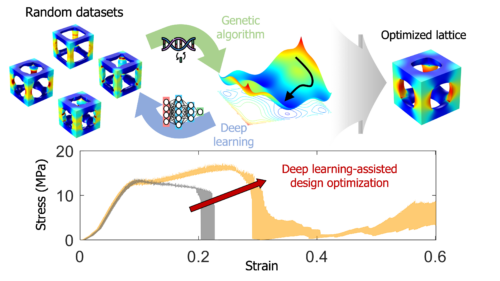

Designing structural materials that simultaneously achieve high stiffness, strength, and damage tolerance remains a central challenge in advanced vehicle and device design. Architected materials address this limitation by enabling precise control of mechanical behavior through geometry-driven design rather than material composition. We have explored adaptive neural network genetic optimization (NN-GO) method for designing architected lattice materials with superior mechanical properties. By employing high-order Bézier curves to parameterize the geometry of lattice beam elements, we expanded the design space beyond traditional linear or spline-based geometries. Learning patterns from the mathematics of aperiodicity, we also created composites tiled by a single “monotile” (the “hat” polykite) that never repeats. This controlled order spreads and deflects cracks in ways periodic honeycombs cannot, yielding gains in terms of mechanical properties, while showing consistent performance independent of loading direction. This translates to damage‑tolerant architectures that are less sensitive to load path uncertainty, a critical advantage for lightweight aerostructures and devices that see complex service conditions.

We develop multi-physics modeling frameworks to reveal how structure governs properties across length scales and guide materials-by-design. At the atomic scale, we used molecular dynamics to show how defect patterns and kirigami-inspired cuts in graphene tune anisotropy, strength, and ductility in controllable ways. At the mesoscale, crack phase-field models coupled with multi-objective Bayesian optimization reveal how chiral aperiodic monotile composites can be architected to steer crack paths and transition between brittle and ductile failure modes while achieving Pareto-optimal combinations of strength, work of fracture, and failure strain. At the process scale, we coupled CFD with ML surrogate models and Bayesian optimization to redesign semiconductor showerheads, achieving significantly more uniform gas flow with an order-of-magnitude reduction in design exploration cost. These efforts provide a cohesive toolkit for linking structure, processing, and performance in complex, multi-functional materials.

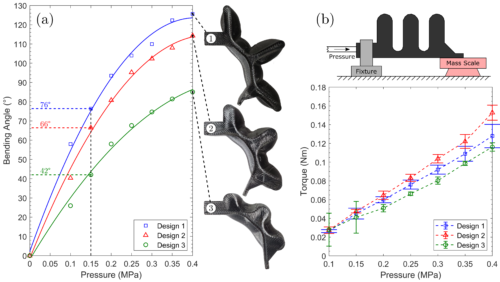

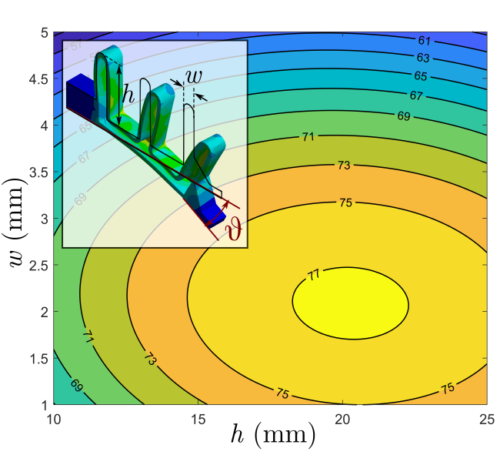

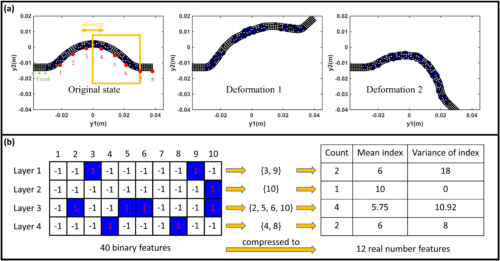

Soft robotics offers a different vision for robotics: one where compliance, adaptability, and safety emerge from the materials and geometry. Many of these capabilities echo biological structures, which deform continuously, distribute forces safely, and adapt seamlessly to unstructured environments. Our lab designs soft robotic actuators that embody these principles while pushing the limits of what soft machines can achieve in manipulation, sensing, and adaptive interaction. We developed a computational-experimental framework to map and optimize the design space of 3D-printed pneumatic bending actuators, revealing how bellow geometry governs bending angle, torque output, and compliance. Using finite element simulations, machine-learning-based regression models, and targeted experiments, we identified key trade-offs (such as when maximizing bending range decreases torque capacity) and established principles for rapid, customizable soft actuator design. Building on this foundation, we created a hybrid physics-informed and data-driven modeling framework capable of predicting full soft gripper gestures (including large deformations, contact interactions, and gravity effects) at speeds orders of magnitude faster than traditional finite element analysis. By training neural-network surrogate models on pneumatic joint behavior and embedding them into a differentiable mechanics-based solver, we enabled real-time prediction of complex soft robotic interactions. This allows soft grippers to be modeled, optimized, and controlled with unprecedented efficiency, providing a path toward intelligent, adaptive soft manipulators. Our goal is to create soft robotic systems that are programmable, reliable, and capable of safe interaction across biomedical, aerospace, and industrial applications.